This second knife was my first attempt at forging - a cheeky little utility knife. Would be great for fishing, (but pretty nifty at slicing onions and deboning too I have found).

The blade is stainless steel from a broken bicycle D-lock, the handle is yew carved green from a log found in a Chilterns forest after treeworkers had been at their thinning work..

The blades for both of these efforts were forged from the steel rod of this old broken D-lock. How cool is that? I'm not sure what the composition of bike lock steel is, but it is obviously stainless and presumably is hardened, so should be good for a blade.

Here is an offcut fro the D-lock being heated to red hot on the barbecue, using BBQ briquettes. These are formed lozenges of charcoal. Real coal is probably a lot better for heat, but also is pretty oily and you can't cook food on it after forging. Of course, barbecues don't normally get this hot. There's a fan acting as a bellows.

Here it is - a camping airbed inflator fan. They are reasonably pokey and can handle being left on for a while. A typical smithing session can take an hour. This one copes with prolonged use. I have seen hairdryers used. They are used normally for quite a long time continuously, so should be good too.

The pipe is domestic water piping sealed at the far end with lots of holes drilled to spread the airflow evenly.

Here, you can see the holes and the end that has been hammered over as a cleat to seal it.

This is another piece of the old D-lock being heated

Some big hammers were used in the making of these tools. Last time I counted, I own at least 13 hammers. That is funny. Here are two heavy ones on the anvil.

The metal should be red hot at least when hammering. Here's the smaller knife being formed from the bar.

And here is the larger carving knife taking a hammering.

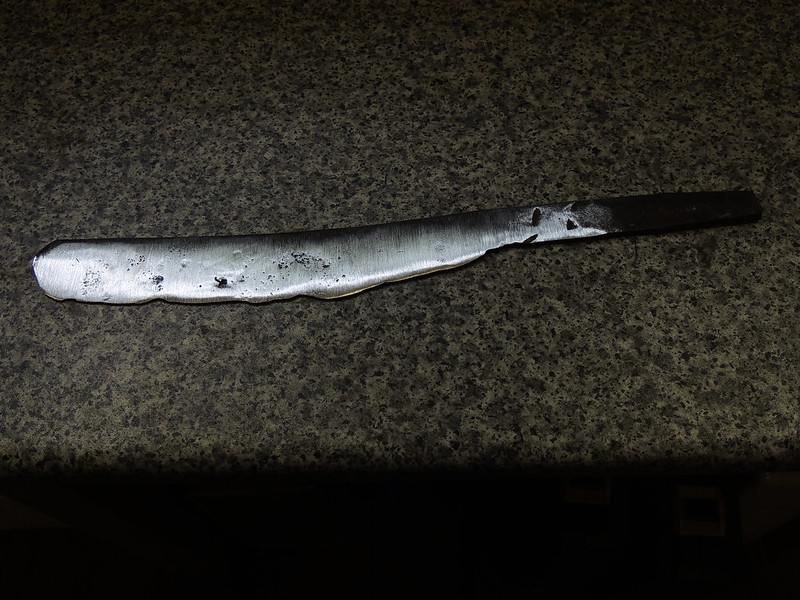

Which turns into this. The original size of the bar can be seen clearly.

Eventually it will end up like this

or like this afer some smoothing

The handle was carved to a rough former shape. The chisel and round mallet are tools I made previously... Proved handy to test this

Then rounded off on my beloved 50-year-old industrial-grade, belt sander. Sigh, how lovely...

The sander is used to shape both blade and handle

Here is the large carving knife, ready to fit the handle.

To get the handle to fit required a lot of fine handheld routing with the dremel

These bad boys are brass screws, shortly to be rivets!

And the finished lovelies...

Carver...

Utility knife...

No comments:

Post a Comment